ALL DUCT LINE

| Duct Products

sound attenuator

General Information On Noise :

Noise is generally accepted as unwanted sound. Noise in a ventilation system is a very complex and diverse phenomenon. There are often many noise sources from each other; however, it is very important to be able to separate them so that the appropriate sound attenuator can be installed.

Noise Sources:

In principle, the noise sources in a ventilation system can be roughly divided into the following main areas:

1. Fan Noise.

2. Duct Noise.

3. Noise from dampers, leaks, etc.

1. Fan Noise :

Noise from the fan can be divided into air noise and operating noise. Air flow noise is a function of the velocity and pressure. Operating noise comes from the fan motor, belt drives, bearings, etc. the air flow noise is usually the worst problem. The critical frequency is often the fan impeller frequency, fs.

fs = n/60 . s, Hz

n = number of revolutions, rpm.

s = number of blades.

2- Duct Noise :

Duct noise is generated primarily when the air flow passes sharp edges, dampers, turning vanes in rectangular elbows and poorly installed saddle taps. Any obstruction to the air flow will cause turbulence and noise. Secondary duct noise may also originate from the transmission of noise through the duct from room to room.

3- Damper Noise, valve Noise, etc. :

Noise may also be caused near valves, dampers as the air flow passes through relatively small holes. Noise may also be caused by poor joints or leaks.

How to select Sound Attenuation

1. The first step is to analyze your system and determine the amount of noise reduction required. This is expressed as insertion loss in decibels when referring to silencer acoustical performance data.

2. You will also need to know the maximum amount of resistance you can add to the air flow that your system can handle. This is expressed as static pressure drop.

3. Additional resistance for the fan or air moving equipment in the system will have to be able to overcome to maintain the same air flow and efficiency.

Data required for selecting proper Attenuator

1. The design insertion losses (IL) at each octave and frequency, ranging from 63 Hz up to 8000 Hz.

2. The design airflow rate through each silencer with the maximum permissible pressure drop across each silencer.

3. Duct connection size, and the maximum permissible length for the silencer (if applicable). Maximum static pressure drop.

4. Room Dimensions ( W x H x L).

Note:1

If the information is NOT available on S.No.1 above, fan sound power spectrum and the design noise criteria (NC) shall be required. Under this condition, Egy air make scertain assumptions while selecting the attenuators. Please note that the selection made by Egy air must be checked and approved by the design consultant in the absence o the required/specified IL. As an equipment manufacturer, Egy air is not responsible for the system design.

Note:2

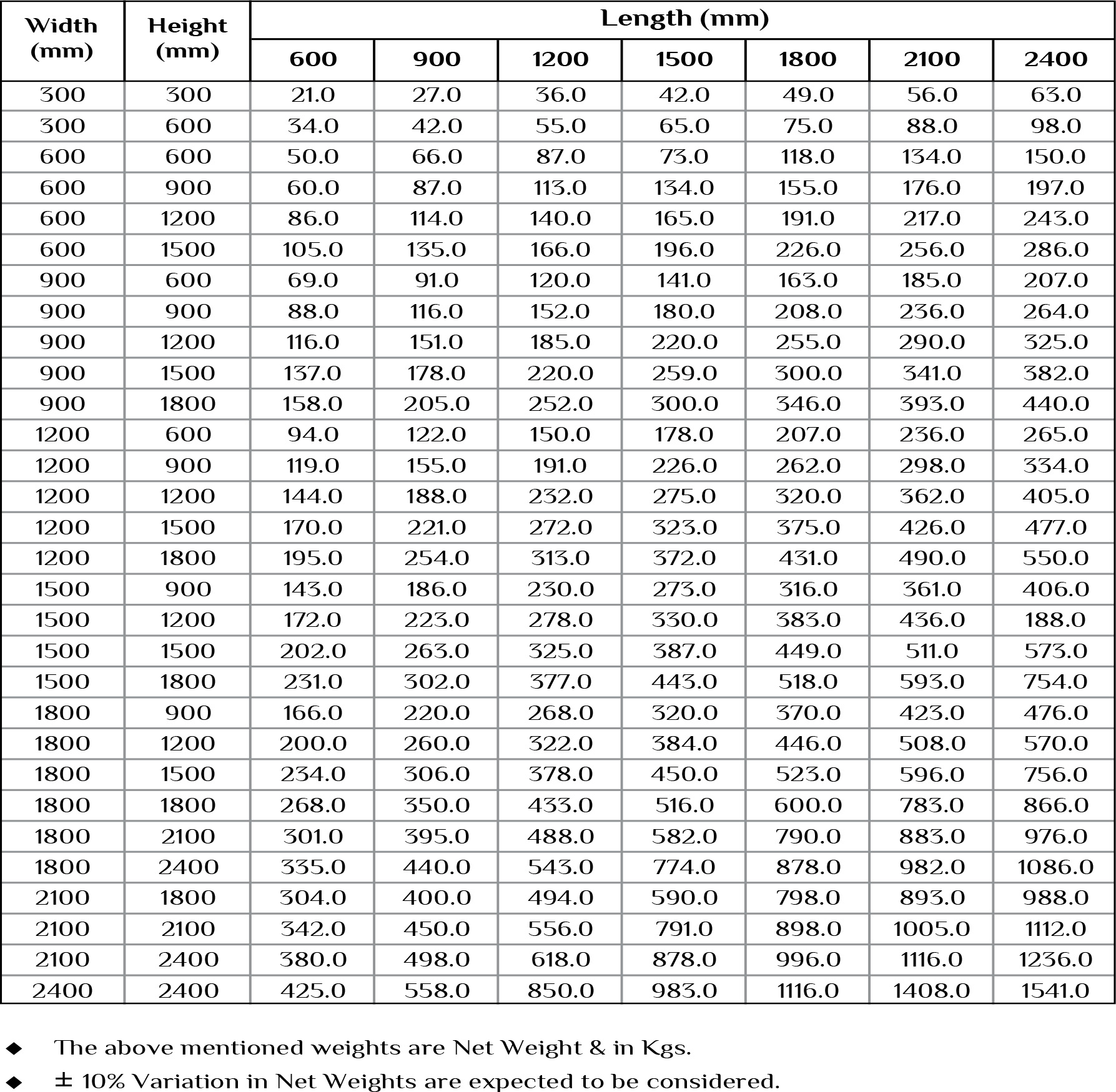

Please note that Egy air’s standard silencer lengths are 600, 900, 1200,

1500, 1800, 2100 & 2400mm long. Once you have this information you will be able to simply select the silencer size and model that matches your criteria.

Noise Definitions

Sound Power Level (SWL) Vs Sound Pressure Level (SPL):

The difference between SPL and SWL: SPL is the sound pressure level =20 log P/Pref. P is sound pres-sure in N/m2 and Pref = 20 x 10-6 N/m2, while SWL is sound power level = 10 log W/Wref, where W is sound intensity in Watts and Wref = 10-12 Watt. The sound is is coming out from the source as SWL and when it travels spherically its intensity will be distributed over sphere area which makes it pressure SPL.

Octave Bands:

An octave band is a frequency band where the highest frequency is twice the lowest frequency. For example, an octave filter with a center frequency of 1 kHz has a lower frequency of 707 Hz and an upper frequency of 1.414 kHz. In HVAC Industry, the octave bands in general comprising 63, 125, 250, 500, 1K, 2K, 4K & 8K Hz.

Frequency (Hz):

The pitch of sound. The number of sound pressure waves arriving at a fixed point per second.

Insertion loss:

Insertion Loss is the reduction in the sound power level at the receiver after the silencer is installed (inserted) in the system. Insertion loss is measured as a function of frequency and commonly published in full octave bands ranging from 63 to 8000 Hz.

A silencer’s insertion loss varies depending on whether sound is traveling in the same or opposite direction as airflow. Silencer performance changes with absolute duct velocity. However, airflow velocity generally does not significantly affect silencers giving a pressure drop of 0.35 in. of water or less, including system effects.

Decibel (dB):

The decibel ( dB) is used to measure sound level.

The dB is a logarithmic way of describing a ratio.

The ratio may be power, sound pressure, voltage or intensity or other.

Background Noise & Breakout Noise:

Background Noise is the irreducible noise level measured in the absence of any building occupants when all of known sound sources have been turned off. Breakout noise is the transmission of mechanical equipments or air system noise throughduct walls.

Regenerated Noise:

Regenerated Noise is the sound generated by the duct due to air flow in dB (ref 10-12 watt).

Moreover, regeneration of sound caused by passing of air through duct elements such as dampers, Air outlets, splitters and other installed mechanical components in the Duct.

Reverberant Time:

This is the plus or minus contribution of the room reflections (reverberation) in dB.

Total Pressure Loss:

Total pressure loss is determined by subtracting the differential pressure across the attenuator from the differential pressure across the substitution duct.

A total pressure loss coefficient is calculated for each attenuator by measuring the total pressure loss at five different airflow rates.

Egy air offers all the above Types & Models of Attenuators with a dedicated experience team who can undertake all aspects of computerized sound analysis & do calculate technically to produce a highly engineered solution to your unwanted noise problem and any noise control issue

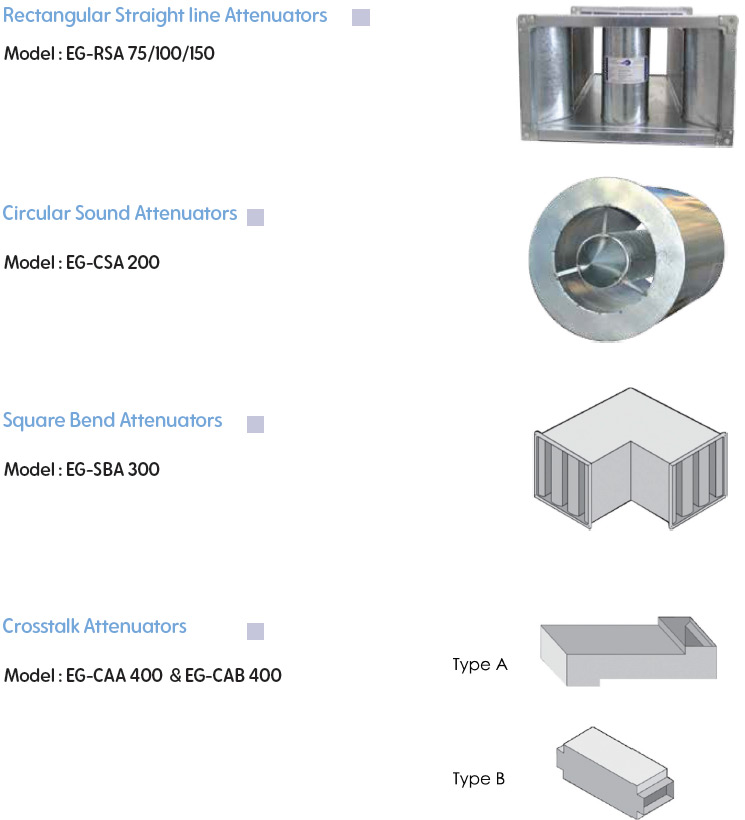

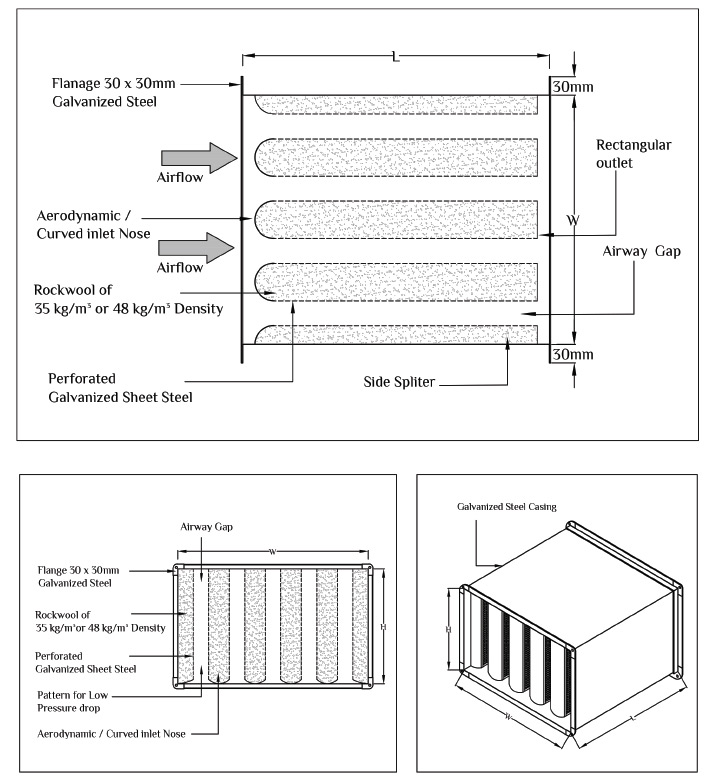

Rectangular Straight Line Attenuators

Model : EG-RSA 75/100/150

Casing

Casing is made of 1.0mm Thick (20 Gauge) galvanized steel. Casing provided with 30 mm flanges as standard. High-pressure duct sealant is applied inside the casing along the length of each seam, and for rectangular casings behind each flanged corner that coincides with a seam, to provide an airtight seal.

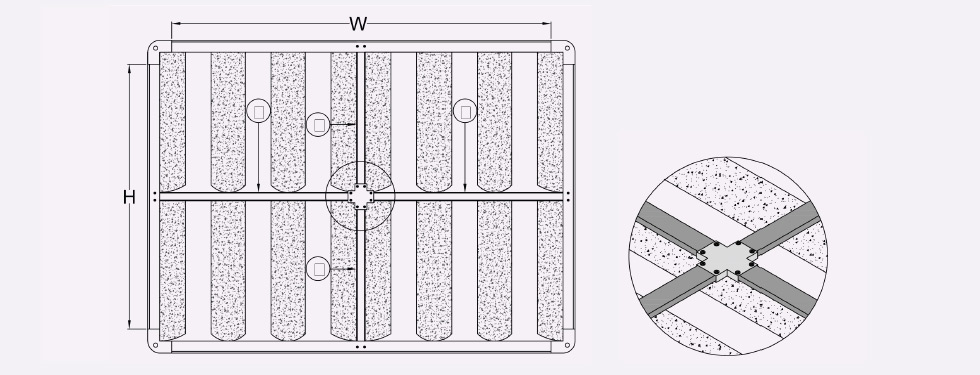

Splitters

Splitters are made of 0.8mm Thick high quality galvanized Perforated Sheets, which are internally insulated with acoustic fiberglass material.

Splitters are formed to thickness options from 75 to 400mm wide centre splitters with different Airway area from 50mm to 250mm. The Attenuator shall be provided with Side Splitters.

All internal splitters having aerodynamic shaped fairings, being mechanically lock-formed to the perforated metal splitter casing and stiffened in such a way as to eliminate splitter deformation.

Airway Area & Width

Airway area & Width may differ based on

technical calculations & Attenuator final

dimensions.

Flanges

Attenuators fitted with external galvanized steel flanges of 30mm with Corners of 105mm will help in arresting leakages, which also provides firmness & stability to Ducts, thereby creating effective barrier against

pressure drop. Flange corner holes fitted with M8 nutserts to enable easy connection

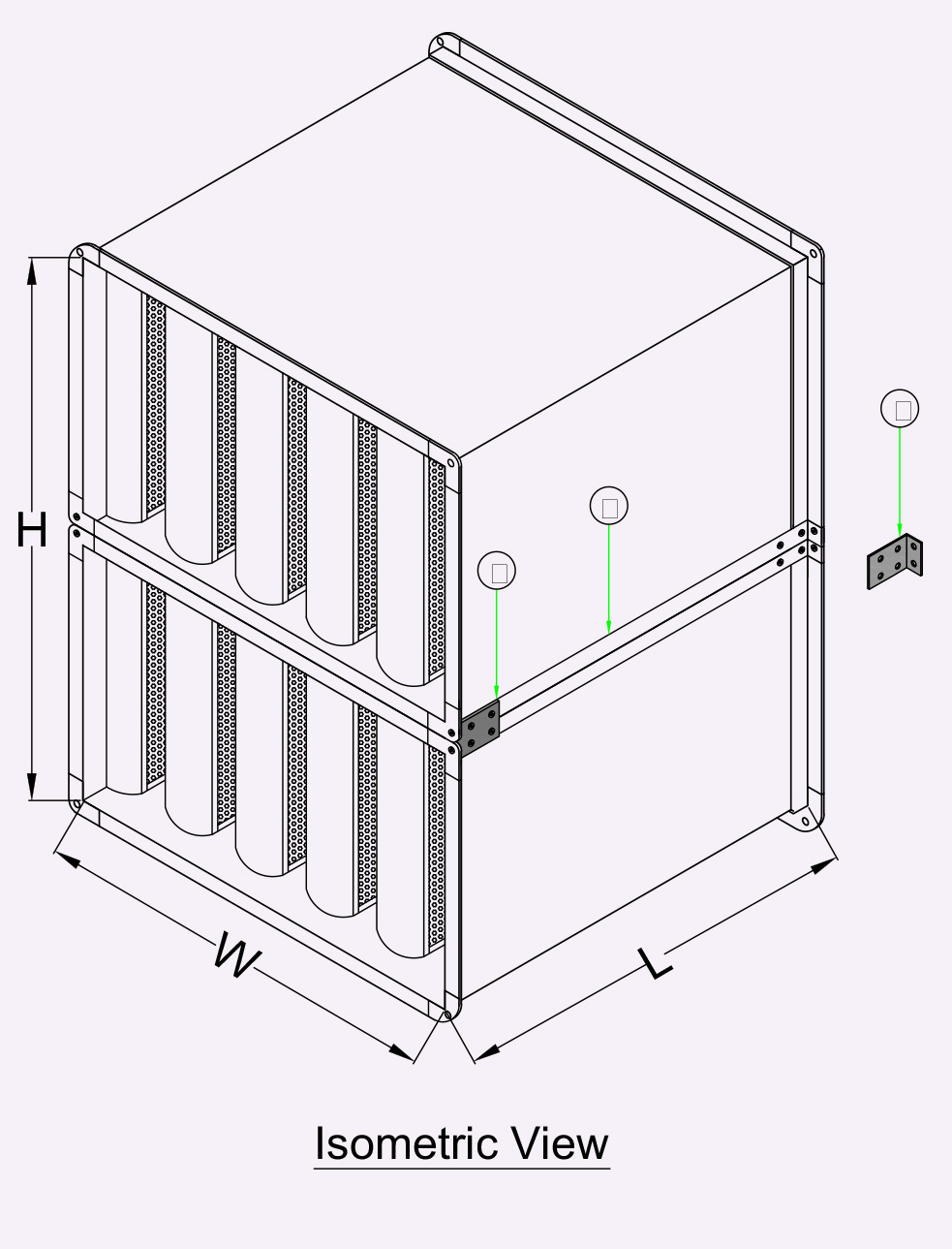

Single & Multiple Section Assembly

Egy air attenuators are supplied in Multiple Sections, when any of the below dimensions are exceeded :

W=2100, H= 1800 L = 2100 mm.

The assembly of multiple section attenuators will be carried out by others at site, based on the manufacturers instruction & guidelines.

Attenuator Dimensional Details

Rectangular Straight Line Attenuators

Model : EG-RSA 75/100/150

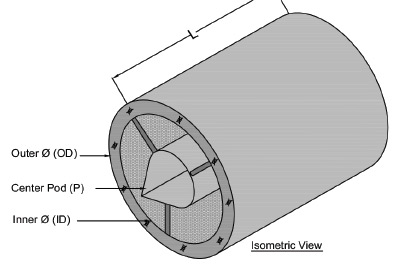

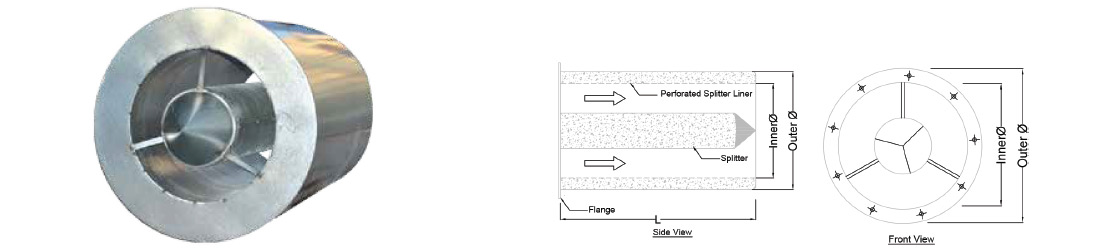

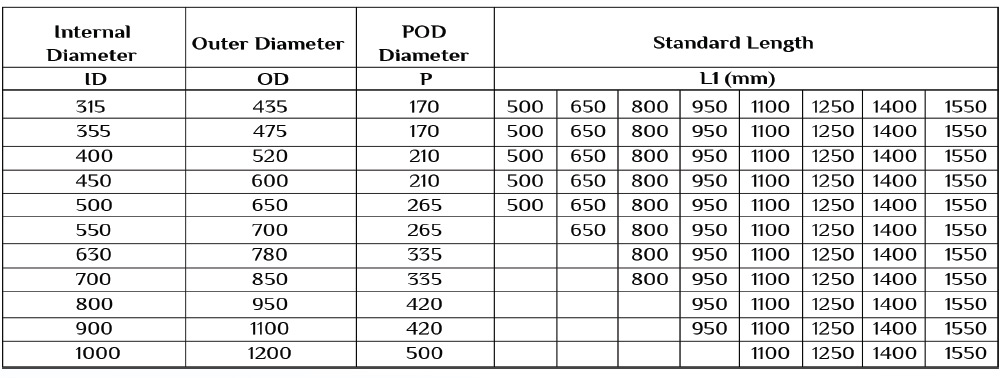

Circular Sound Attenuators

Model : EG-CSA 200

Egy air Circular Sound Attenuator constructed from Galvanized sheet steel, with a peripheral out of airstreams acoustic lining. Casing provided with end ring flanges suitable for direct connection to circular fans or flanged ducts.

Casing

Casing is made of 1.0mm Thick (20 Gauge) galvanized steel. Casing provided with 30mm flanges as standard which will be sealed with Mastic Sealant to prevent leakage of Air. Circular Sound Attenuators are constructed with the following dimensions :

Inner Dia— 300 to 1000 mm

Outer Dia— 435 to 1200 mm

High-pressure duct sealant is applied inside the casing along the length of each seam, and for rectangular casings behind each flanged corner that coincides with a seam, to provide an airtight seal.

Flanges

Attenuators fitted with external galvanized steel end ring flanges suitable for direct connection to circular fans or flanged ducts.

Available Size

Sound Attenuators Specification

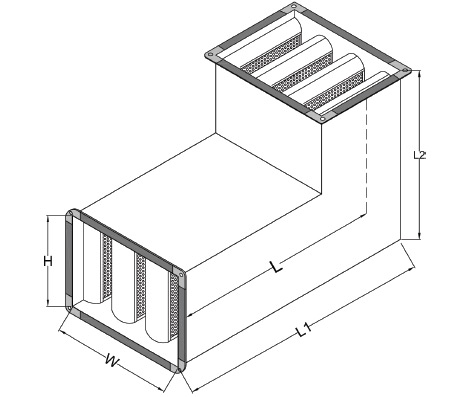

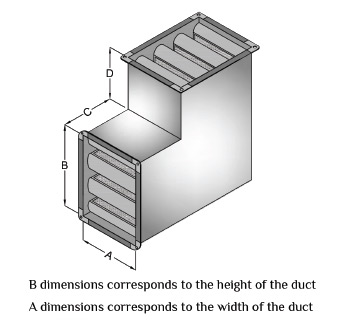

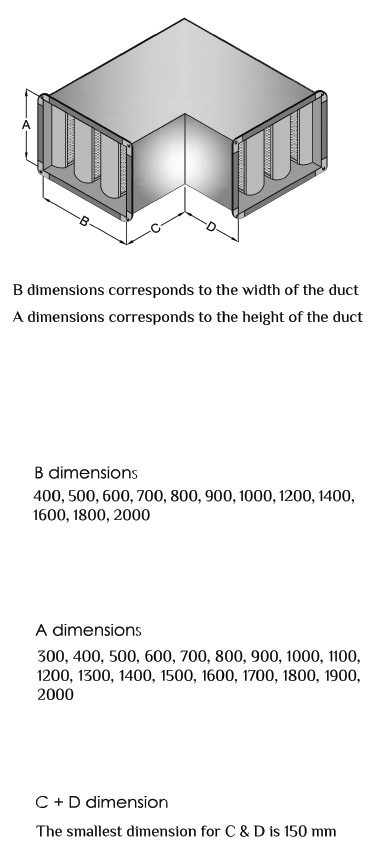

Square Bend Attenuators

Model : EG-SBA 300

Casing is made of 1.0mm Thick (20 Gauge) galvanized steel. Casing provided with 30mm flanges as standard. High-pressure duct sealant is applied inside the casing along the length of each seam, and for rectangular casings behind each flanged corner that coincides with a seam, to provide an airtight seal.

Splitters

Splitters are made of 0.8mm Thick high quality Galvanized Perforated Sheets, which are internally insulated with acoustic fiberglass material.

Splitters are formed to thickness options from 75 to 400mm wide centre splitters with different Airway area from 50mm to 250mm.

The Attenuator shall be provided with Side Splitters.

All internal splitters having aerodynamic shaped fairings, being mechanically lockformed to the perforated metal splitter casing

and stiffened in such a way as to eliminate splitter deformation.

Vertical or Horizontal Splitter orientations

Airway Area & Width

Airway area & Width may differ based ontechnical calculations & Attenuator final dimensions.

Flanges

Attenuators fitted with external galvanized steel flanges of 30mm with Corners of 105mm will help in arresting leakages, which also

provides firmness & stability to Ducts, thereby creating effective barrier against pressure drop.

Flange corner holes fitted with M8 nutserts to enable easy connection.

Single & Multiple Section Assembly Egy air attenuators are supplied in Multiple Sections, when any of the below dimensions are exceeded :

W=2100, H= 1800 L = 2100 mm.

The assembly of multiple section attenuators will be carried out by others at site, based on the manufacturers instruction & guidelines

Square Bend Attenuators

Model : EG-SBA 300

Sizing / Dimensions

Dampers, duct bends and other equipment in the vicinity of the sound attenuator will increase its inherent sound generation and pressure drop. The specified data are based on a uniform air stream in and out of the sound attenuator.

If perforated sheet steel covers the baffle surfaces, this increases the level of inherent sound generation.

In the standard version, Egy air has outer dimensions equivalent to the connection size. The outer dimensions are specified in the Technical Data Table.

If recessed connections are selected, this design will decrease the p value (and thus the pressure drop) of the sound attenuator. The advantages achieved by placing a part of the sound attenuator’s active section outside the airflow enable not only a lower pressure drop, but also a more favourable velocity profile.

Sound Attenuators Specification

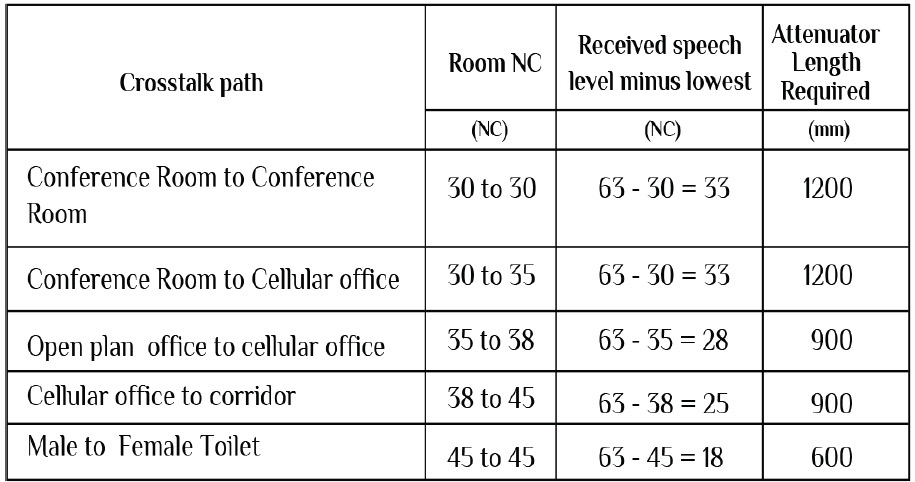

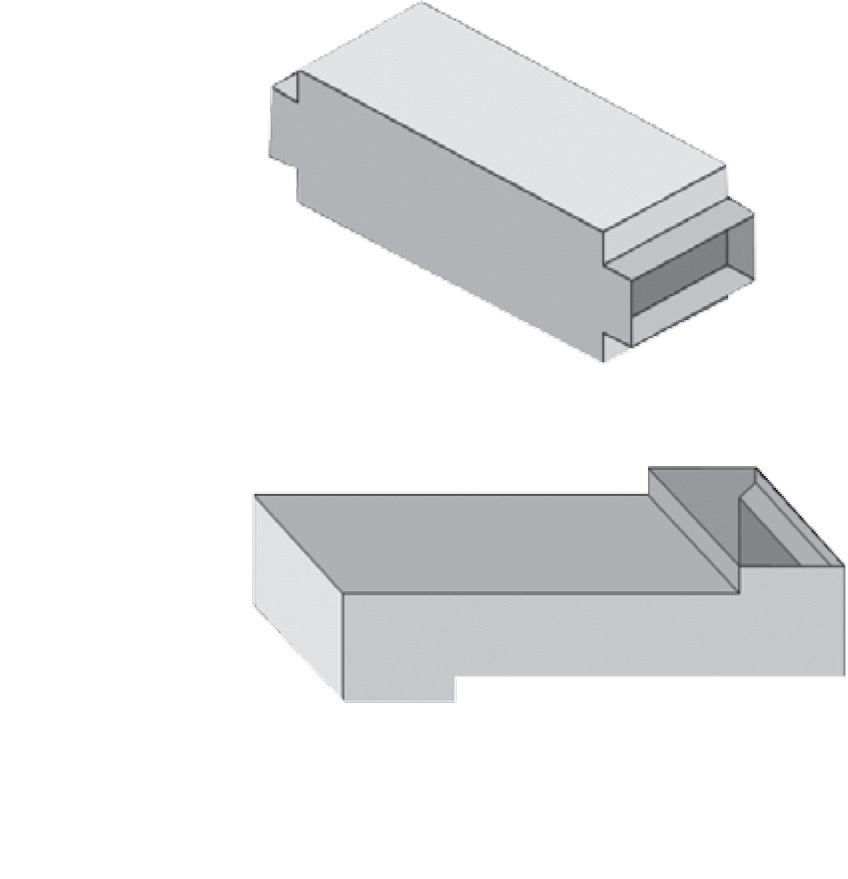

Crosstalk Attenuators

Model : EG-CAA 400 & EG-CAB 400

Casing

Casing is made of 1.0mm Thick (20 Gauge) galvanized steel. Casing provided with 30mm flanges as standard which will be sealed with High-pressure duct sealant.

Selection of Crosstalk Attenuators

For an accurate and quick selection of Crosstalk attenuators, it is necessary to consider the following aspects :

A. The level of speech reaching the receiving room:

The source of crosstalk noise assumed to be raised speech, for which the average sound pressure level is (500-4K-Hz) is 70 dB. The room to room acoustic loss for a typical common ductwork system or via the ceiling void is approximately 7dB, therefore the average

speech level within the receive room is taken to be 70- 7 = 63 dB. B. The Noise criteria for the design of mechanical services in each space

being considered :

• If crosstalk is being assessed between two adjacent room areas with different noise criteria, then the lowest criteria should be used.

• Substract the required NC level from the received speech level to give the additional average insertion loss requirement.

Example :

Air volume 0.09 m3/s ducted crosstalk attenuation required between NC 45 Toilet areas.

Attenuator cross-section required to maintain 1.5 m/s is calculated by (Volume / face velocity) 0.09 / 1.5 = 0.05 m2.

Typical Attenuator cross-sections for 0.06m2 face area :

300 x 200, 400 x 150mm. For NC 45 areas, insertion loss requirements = 63 – 45 = 18 dB, therefore, 600mm long attenuator is

selected.

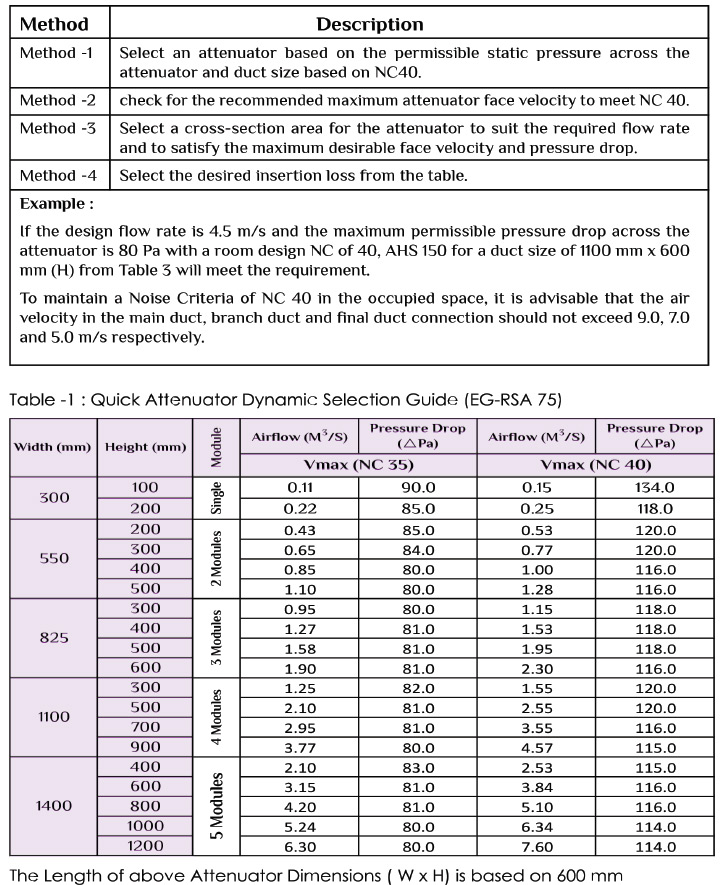

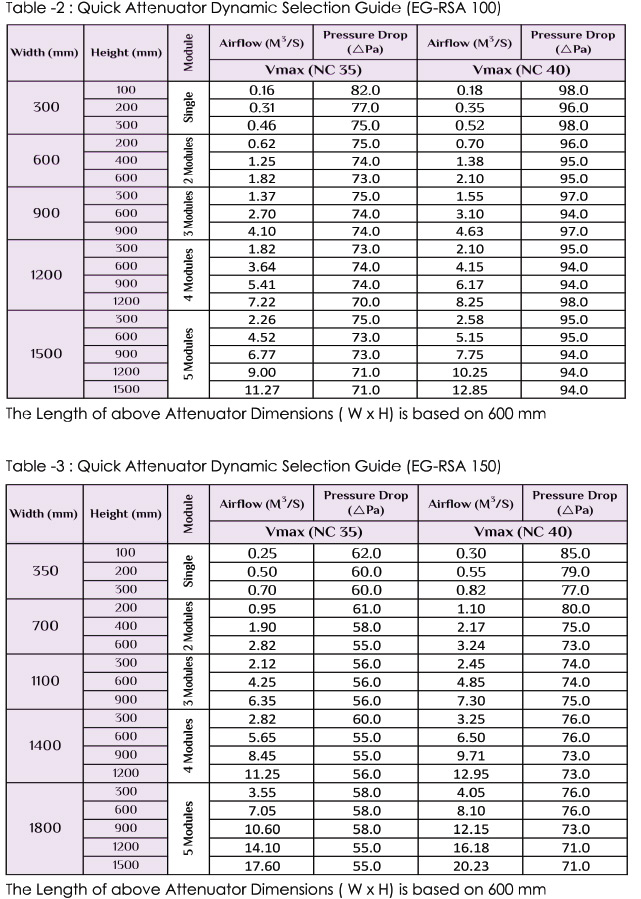

Quick Attenuator Selection Guide

Egy air Attenuator Selection Method stipulated on the below table shall be kept for an easy & quick assistance to the Design Engineer to carry out a quick selection for the attenuators at preliminary design stage, based on the design Noise Criteria of NC 40. This method should only be used when the required insertion loss has not been determined

Quick Attenuator Selection Guide

Installation Details and Guidelines

Rectangular sound attenuators are supplied in multiple modules of many different sizes for convenience and economy in transport, handling and installation. When sound attenuator banks are large, multiple modules are supplied loose for erection at the job site. To avoid possible leaks and damage, two factors need to be considered.

The first, fastening the individual sound attenuator modules together, and the second, sealing the joints between assembled modules to prevent leakage. There are many methods of assembling and sealing multiple modules.

Attachment to Duct Work

Attachment to ductwork can be achieved by one of the following methods:

• S-clip with sheet metal screws and tape.

• Slip or lap joint with sheet metal screws and

tape.

• Angle flanges with gaskets and bolts.

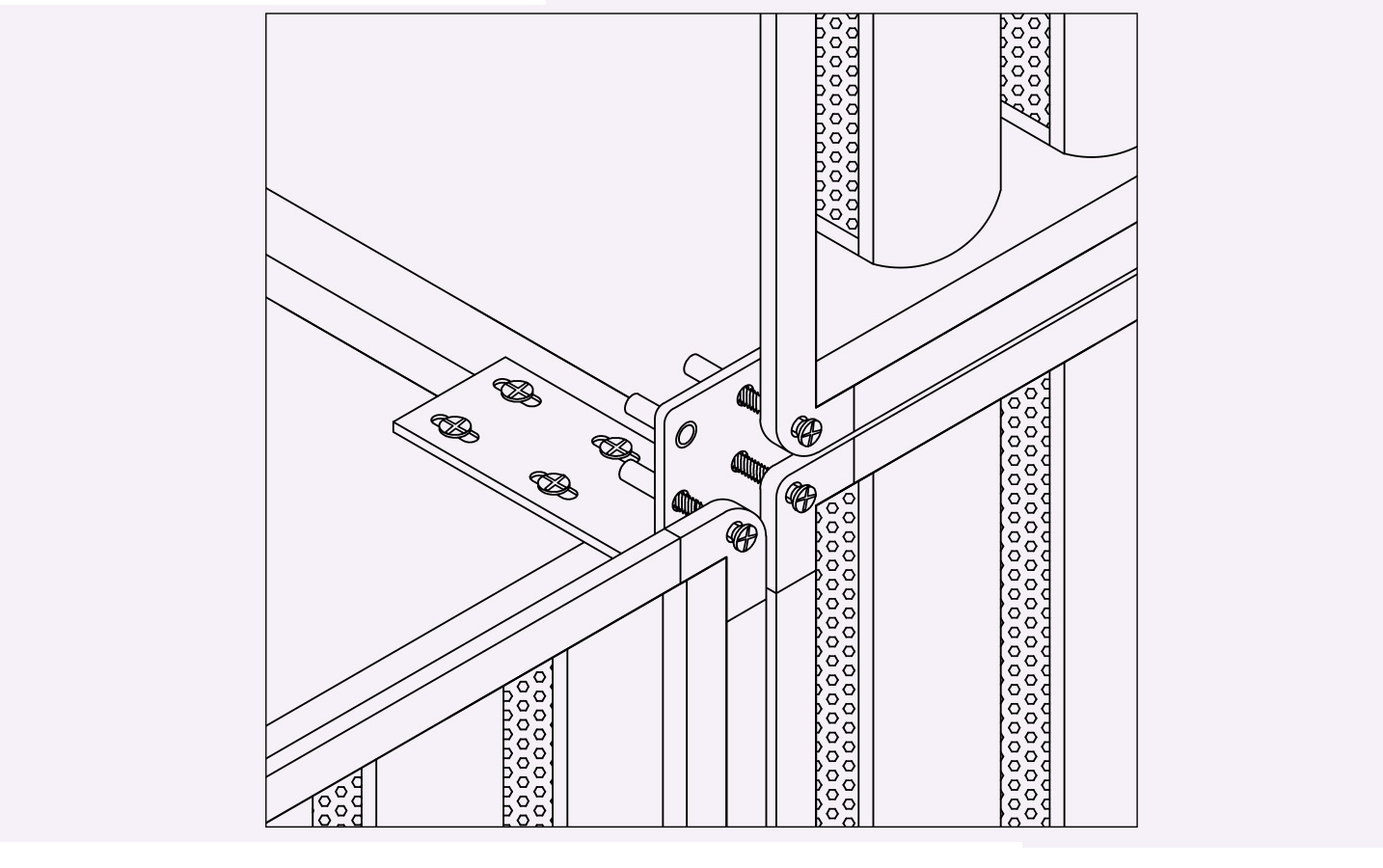

A) Joining adjacent Sections.

1. Lay out and align the sections so that the external rails on each sections are on the correct and matching faces (1).

2. Bring adjacent modules together, with the rails abutting. Use speed clamps or G-Clams or similar as required to ensure tight fit.

3. The modular joining Brackets (2) can then be fixed to the rails and to the flanges of adjacent modules using the supplied M8 countersunk screws.

4. Fixings are made through the brackets into nutserts in each of the mating rails on the adjacent attenuator modules. Two fixings are then made through the flange corner holes into the nutserts in the bracket.

Each Modular Joining Bracket (2) incorporates slots for four fixings and nutserts for two fixings. This allows for fixings into the rails through the flanges of adjacent modules as shown. Fix the screws loosely first until all fixings are in and the units have been correctly positioned and aligned. The screws should then be tightened.

Installation Details and Guidelines

B) Joining Centre Sections

The views below given an enlarged view of a Modular Centre Joining Bracket in position. This bracket has a larger front face incorporating four nutserts to allow the joining through four separate attenuator module flanges

C) Completion of Asembly

Once all of the sections are joined together, as shown in the view below, then a system of capping channel sections and pieces (1 and 2) can be fitted. These are used to close off the gaps between flanges in the inner sections of the modular attenuator.

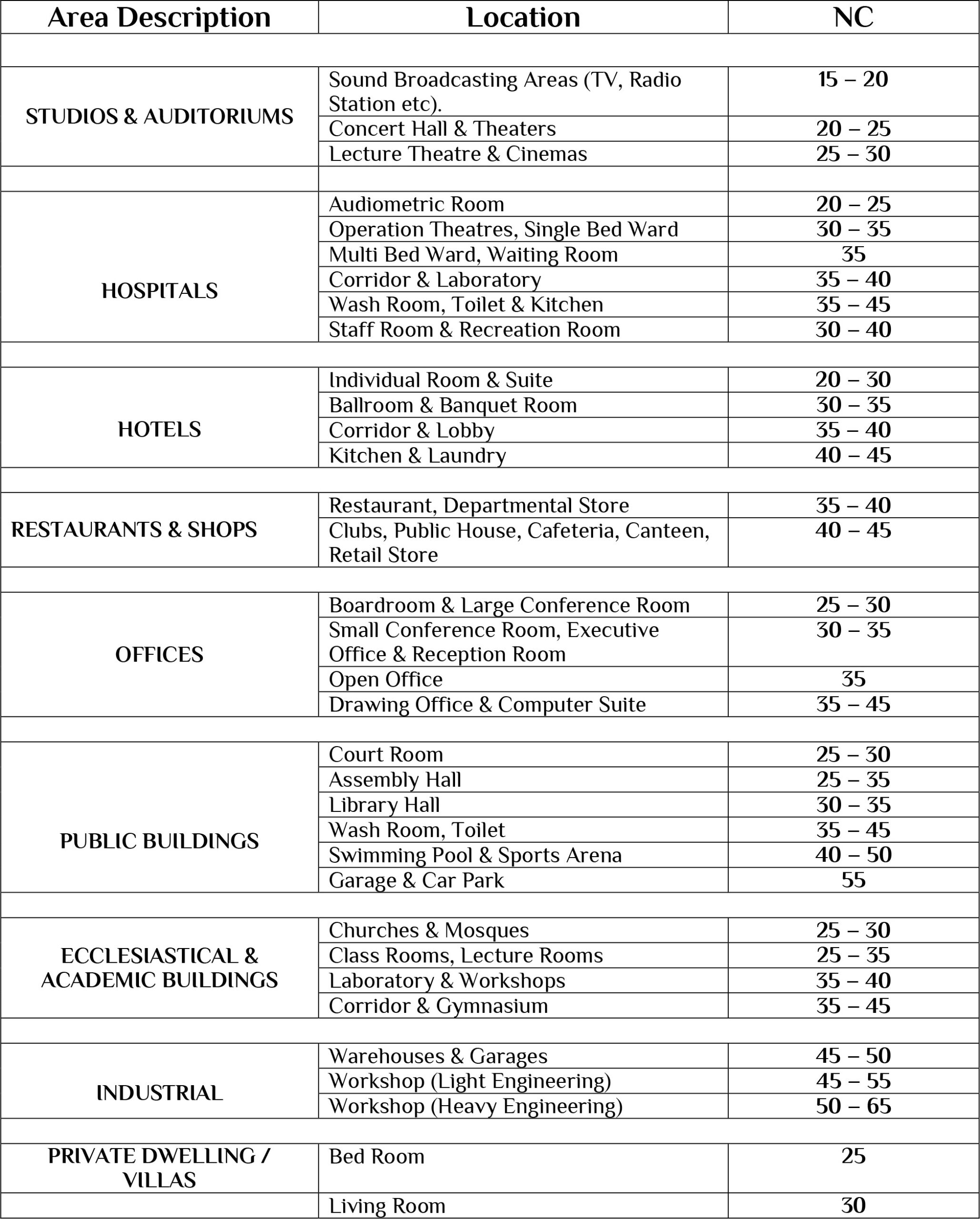

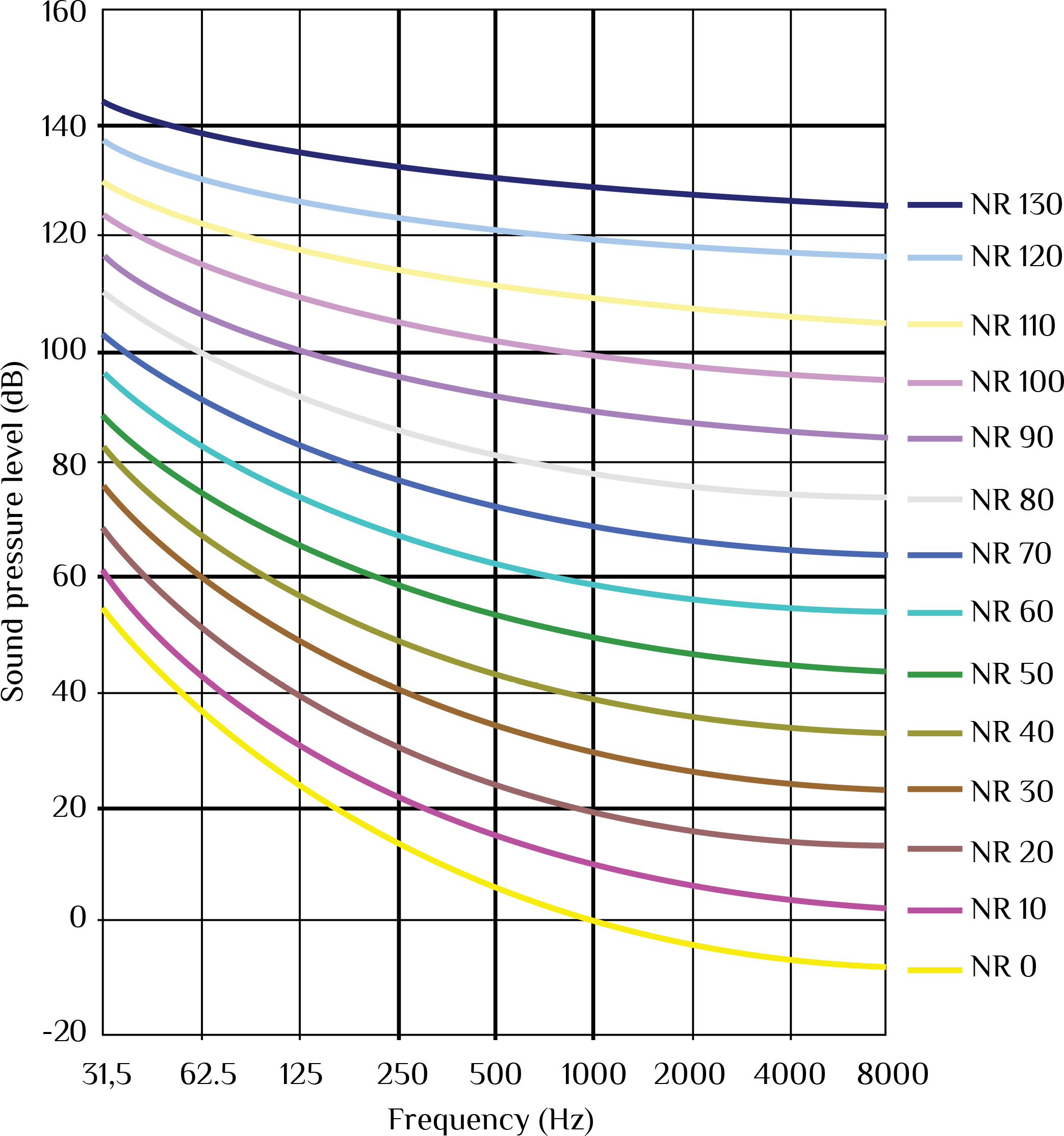

Recommended Noise Criteria For Various Zones

Noise Rating Diagram

Weight Chart For Rectangular Straight Line Attenuator

Sound Attenuators Compliance & Standards

All sound calculations meet international standards ASTM E90,STM E477, ISO 7235, ISO 3741, ISO 140, ISO 3744, ISO 3746, ISO 6798, ISO 8528-10, ASHRAE Handbook & Sound Research Laboratory.

The Construction of all Airwellcare Attenuators are in compliance with SMACNA & DW 144 Standards, ASTM E477, ASTM E84, NFPA 255, UL-723 and silencer dynamic insertion loss and pressure drop ratings in accordance with AMCA & applicable building codes.

Attenuators Acoustic in-fill enveloped with a Melinex Polyester Film coating, which prevents erosion of acoustic fill and/or absorption of moisture by insulation, Bacterial or microbial growth within silencer, as an alternative optional construction, apart from standard supply.

The design flexibility and calculations are based on Attenuator Application & nature of project.

Attenuator casings will comply with one of following pressure classifications:

3 – High Pressure for Class C ductwork systems operating at static pressures between – 750 and + 2000 Pa.

2 – Medium Pressure for Class B ductwork systems operating at static pressures between – 750 and + 1000 Pa.

1 – Low Pressure for Class A ductwork systems operating at static pressures between – 500 and + 500 Pa.

0 – Zero Pressure for static or very low velocity applications where attenuators do not require a pressure classification.

Sound Attenuators Compliance & Standards

Acoustic Property

Fiberglass / Rockwool of 32-35 or 48Kg / M3 Density.

Thickness & density can be changed according to the Technical Calculations, to obtain the optimum performance of the Attenuators.

Non combustible when tested in accordance with BS 476 : Part 4: 1970, ASTM E-136, NFPA255 and UL 723 testing methods. Fill material is class-1 as tested in accordance with ASTM-84.

Fiberglass shall be density calculated to provide the acoustic and aerodynamic

performace.

Tested for Temp. upto 750° C in accordance with DIN 52271.

Meet the requirements of BS 2972 Sec.22 & ASTM C-871, ASTM-C-795, ASTM C-692. ASTM C-177/C-518 & DIN 52612 for low thermal conductivity.

Sound absorption in accordance with BS 3638 & ISO 0354.

Inert, vermin-proof, weather rated non combustible acoustic infill.

The acoustic infill material complies with Class ‘O’ of the U.K.’s Building Regulations

Combustion Ratings

Combustion ratings for acoustic media shall be equal to or less than the combustion ratings noted below when tested in accordance with ASTM E84, UL723 and NFPA255.

Flame Spread Classification: < 30

Smoke Development Rating: < 25

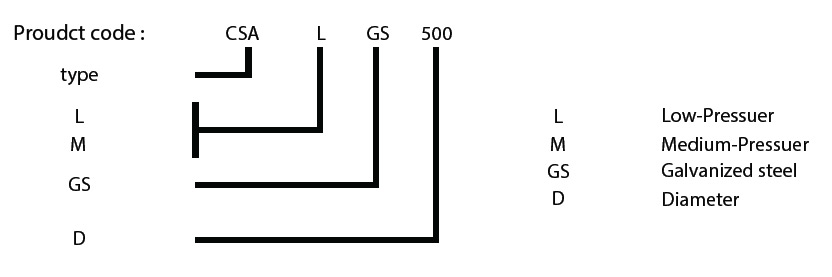

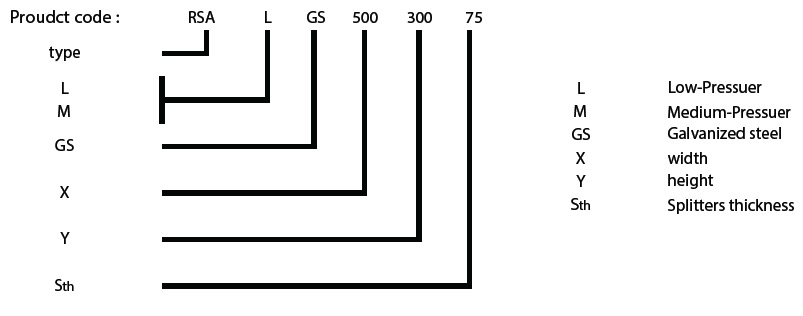

How To Order

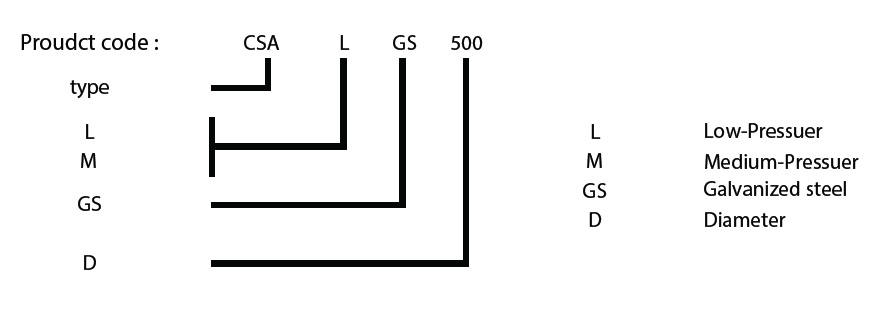

RSA

SCA

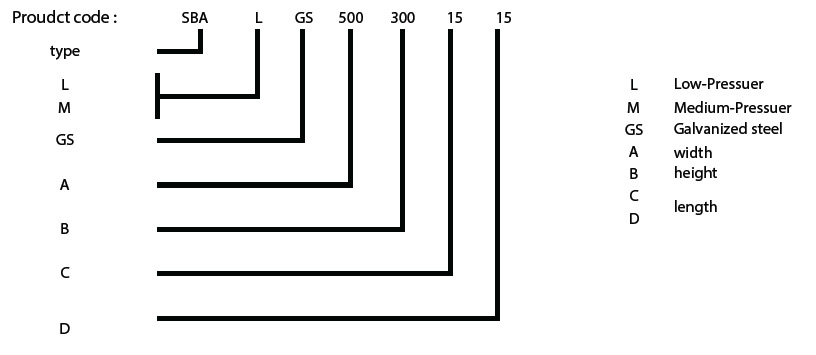

SBA

CAA