air outlets | Ceiling Diffuser

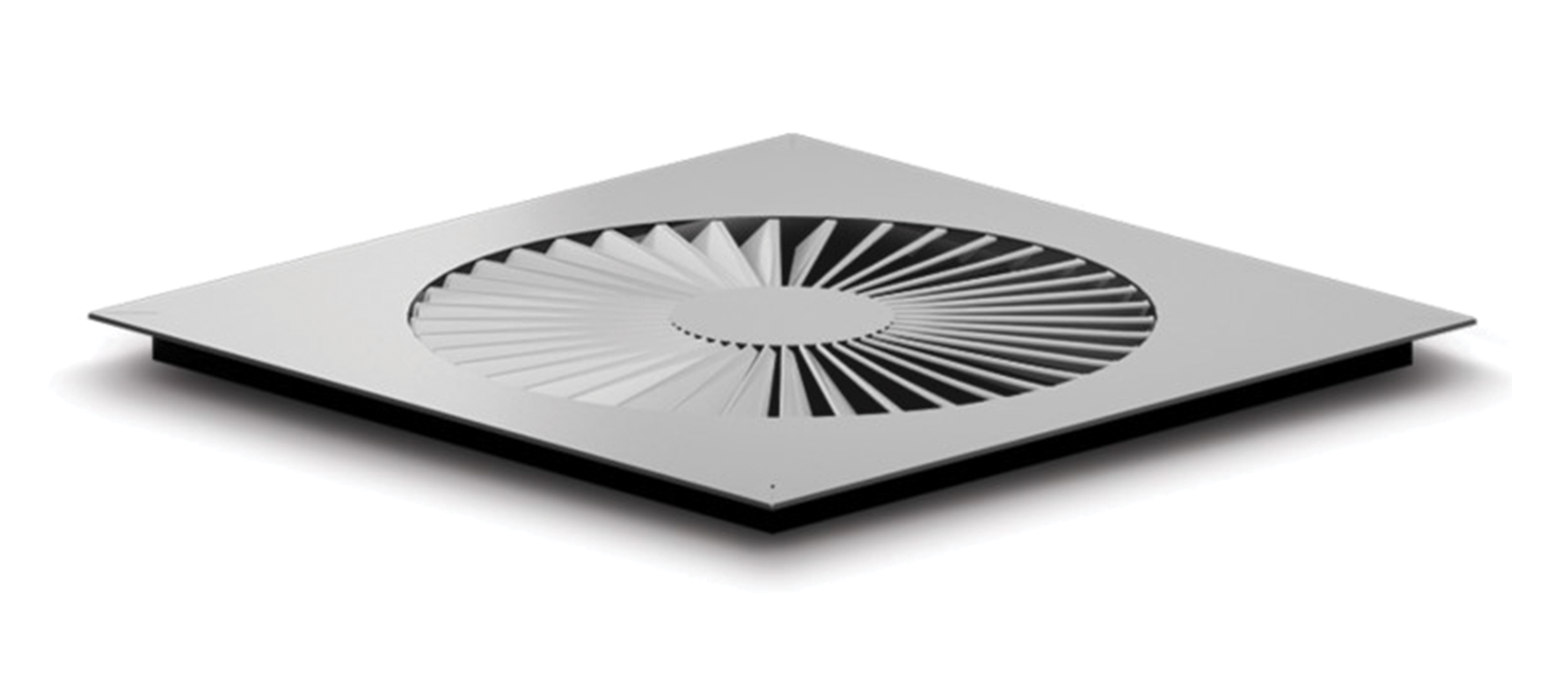

Stamped Swirl Diffuser SD

Construction

Frame

Made from High Quality extruded aluminum Profile with 30 mm flange width1.2 mm (or)1.5 mm thick aluminum sheet.

Blade

A radial array of deflection blades are pressed into a square panel.

Neck

Standard size 250 dia.

Module

600 mm × 600 mm, 595 mm × 595 mm.

Plenum

20 gauge (or) 22 gauge thick GL sheet.

Description

- The frame and blades are made from high quality extruded aluminum profiled construction with Powder coated color finish.

- Supply swirl diffuser and return swirl diffuser can be supplied with volume damper to control static pressure and the air volume flow rate; installed in plenum box.

- The fixed swirl diffuser used for the supply of cooled or heated air.

- A high induction is obtained by the exceptional swirl discharge this quickly reduces the difference in temperature and velocity of the induced air.

- Suitable for VAV terminal boxes.

- This diffuser can also be used for exhaust.

- Foam gasket is sealed around the back of the frame as option to avoid air leakage.

- Powder coated color finish per RAL color codes as standard and flexibility of finish.

Variants

FSD – Q :

Square diffuser face

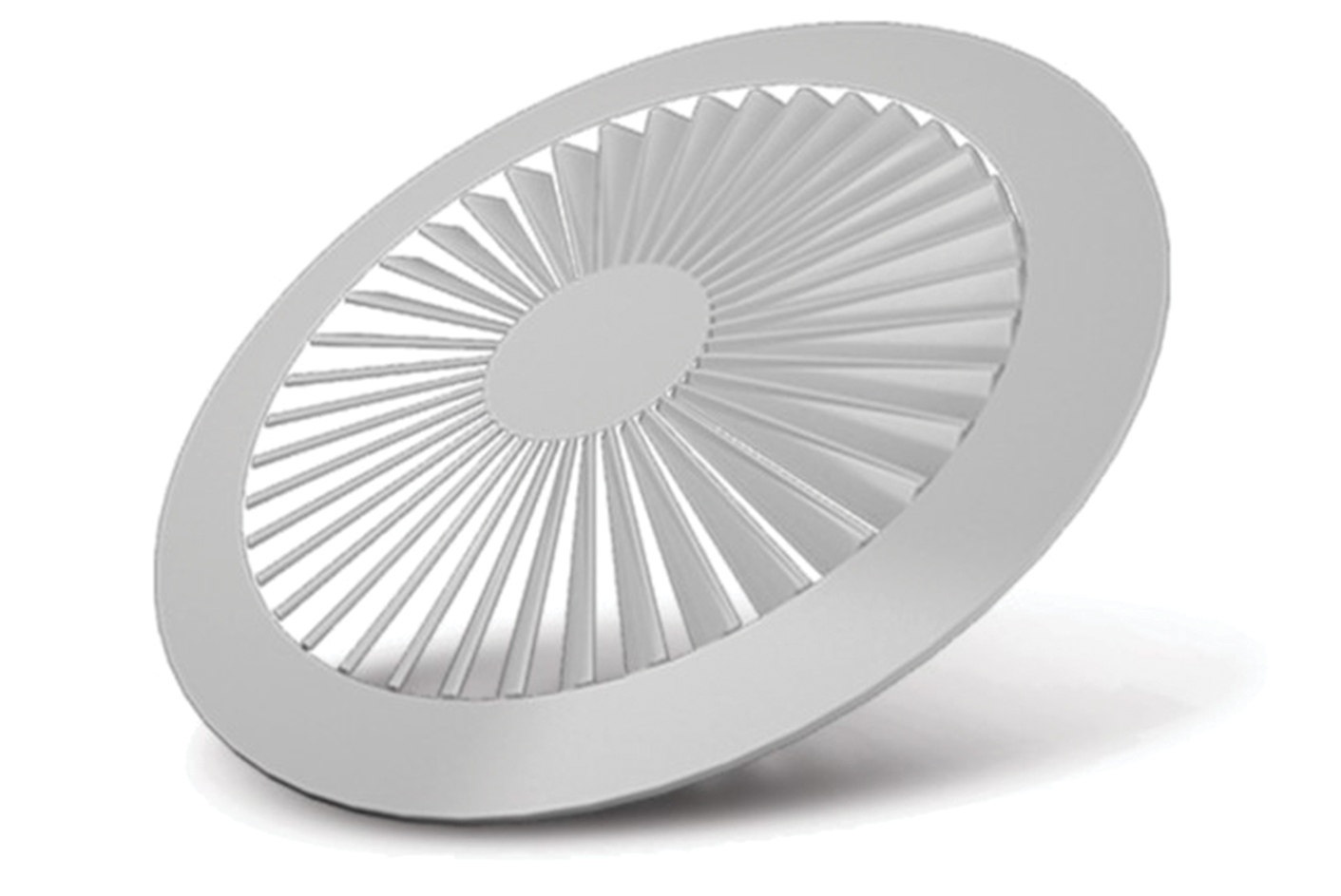

FSD – R :

Circular diffuser face

Connection

H:

Horizontal duct connection

V:

Vertical duct connection

Parts & Characteristics

- Circular or square diffuser face.

- Diffuser faces with radially arranged fixed air control blades.

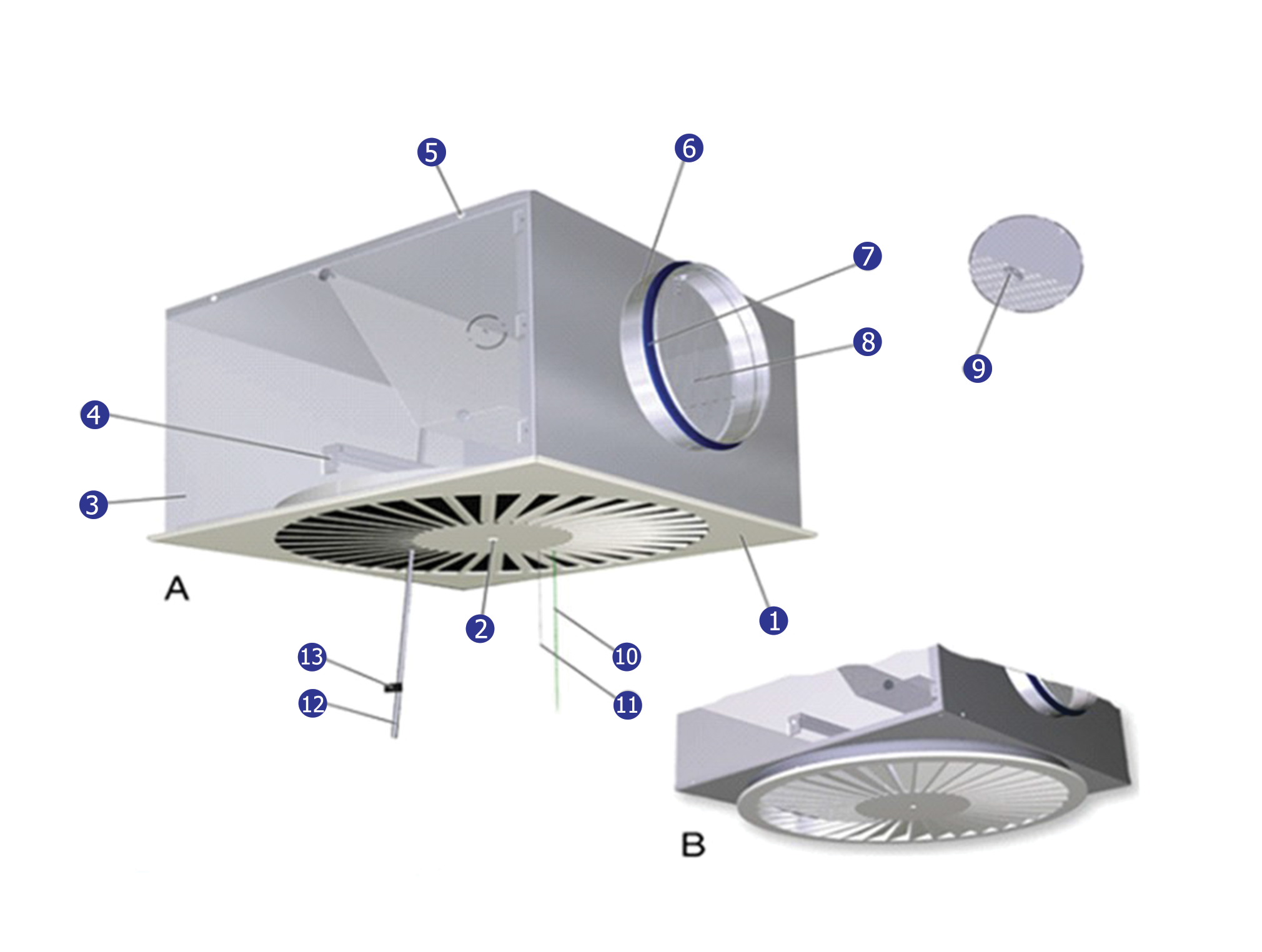

- Plenum box for supply air with an optimized equalizing element that ensures a uniform airflow through the diffuser face.

- Simple installation of the diffuser face due to central fixing screw with decorative cap.

- Damper blade for volume flow rate balancing ( optional ).

Attachments

- Damper blade for volume flow rate balancing or square diffuser face.

- Pressure tap and cord – operated damper blade for volume flow rate balancing with the diffuser face in place.

Accessories

- Lip seal.

Materials & surfaces

- Diffuser face made of galvanized sheet steel.

- Plenum box and cross bar made of galvanized sheet steel.

- Plenum box and made of plastic and galvanized sheet steel.

- Lip seal made of rubber.

- Diffuser face powder – coated RAL 9010 pure white or any other color code.

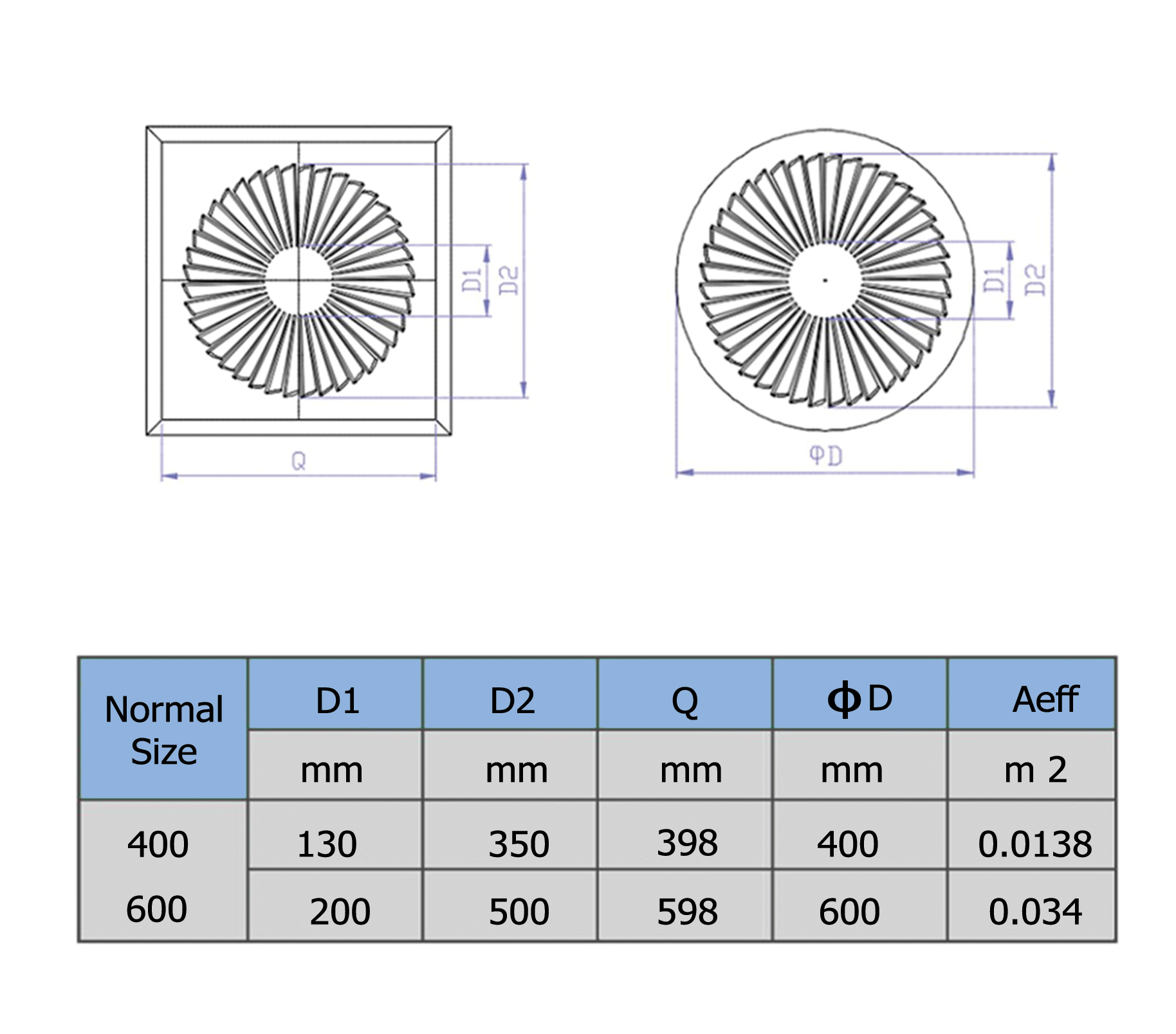

Dimension

Technical Information

- Ceiling swirl diffusers in air conditioning systems create a swirl to supply air to rooms.

- The resulting airflow induces high levels of room air, thereby rapidly reducing the airflow velocity and the temperature difference between supply air and room air.

- Ceiling swirl diffusers allow for large volume flow rates.

- The result is a mixed flow ventilation in comfort zones, with good overall room ventilation, creating only very little turbulence in the occupied zone.

- Type SWF ceiling swirl diffusers have fixed blades.

- Air discharge is horizontal Omni directional.

- The supply air to room air temperature difference may range from -12 to +10 K.

- A damper blade (optional) simplifies volume flow rate balancing for commissioning.

- Pressure tap and cord-operated damper blade (optional) allow for volume flow rate balancing with the diffuser face in place.

- To give rooms an aesthetic, uniform look, Type SWF diffusers may also be used for extract air.

Plenum Box

- 1- Diffuser face

- 2- Central fixing screw

- 3- Plenum box

- 4- Cross bar

- 5- Suspension hole

- 6- Spigot optional

- 7- Lip seal

- 8- Damper blade for volume flow rate balancing

- 9- Pressure tap

- 10-Green cord for closing the damper blade

- 11-White cord for opining the damper blade

- 12-Measuring tube

- 13-Text label indicating plenum box variant

Selection

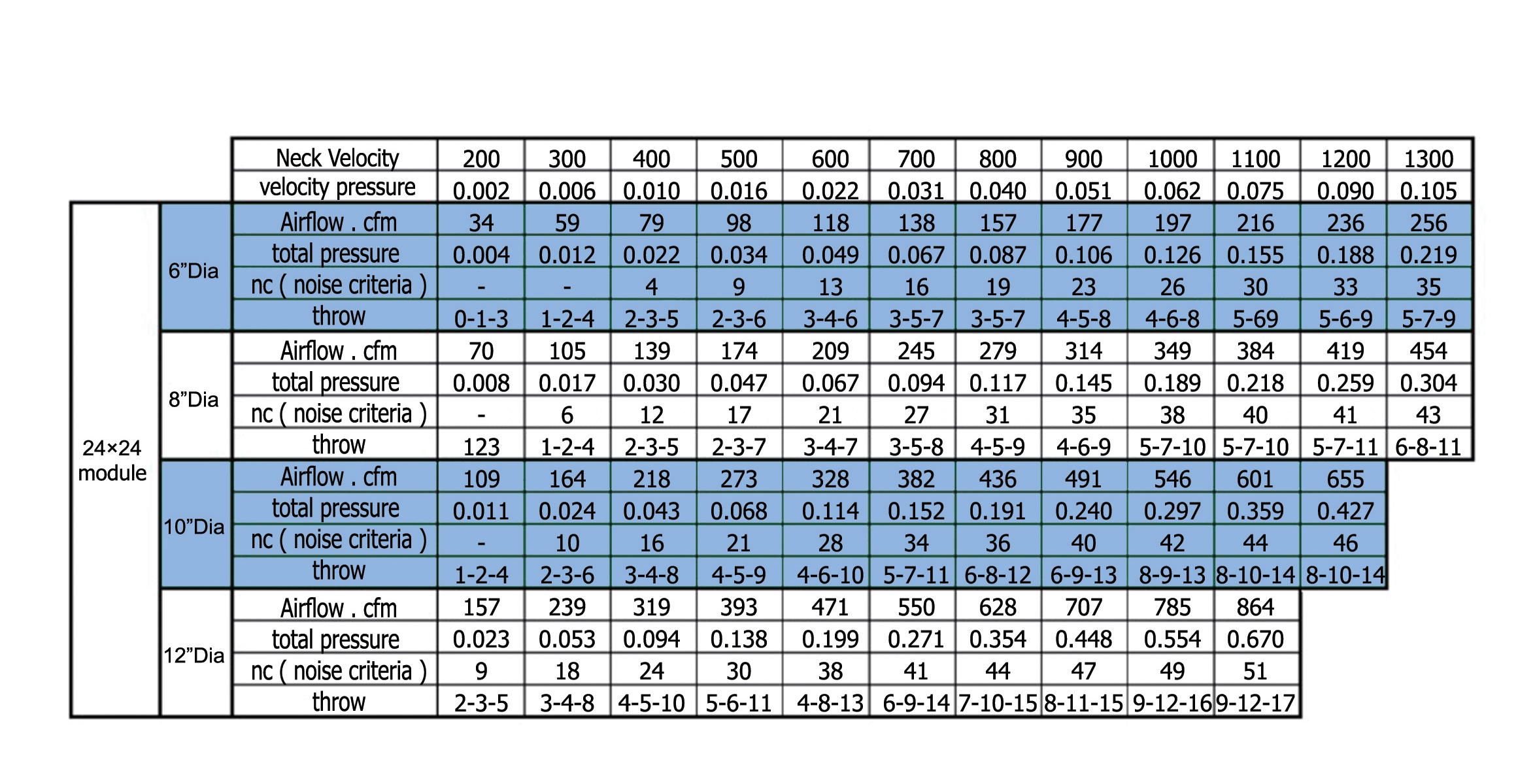

- Data obtained from tests conducted in accordance with ANSI/ASHRAE standard 70-2006. Actual performance with flexible duct inlet, may vary in the field.

- Throw values given are for terminal velocities of 150, 100 and 50 fpm and for isothermal conditions.

- Each NC value represents the noise criteria curve that will not be exceeded by the sound pressure in any of the octave bands, 2 through 7, with a room absorption of 10 dB, re 10-12 watts.

- Dash (-) in space denotes an NC Value of less than 10.

- All pressures are given in inches of water.

- To obtain static pressure, subtract the velocity pressure from the total pressure.

How to order